Views: 0 Author: Site Editor Publish Time: 2026-02-02 Origin: Site

How Color-Coated Steel Sheets Achieve Modern Cladding Systems

Steel structure buildings are springing up like mushrooms after rain, and color-coated steel sheets serve as custom-made "clothing" for these "steel bones," providing both protection and aesthetic appeal.

1. Core Definition

The "Colorful Skin" of Steel Structure Materials Systems

Color-coated steel sheets undertake a dual role of enclosure and decoration in steel structure buildings. They are no longer merely building materials; they are the "second skin" of steel structures.

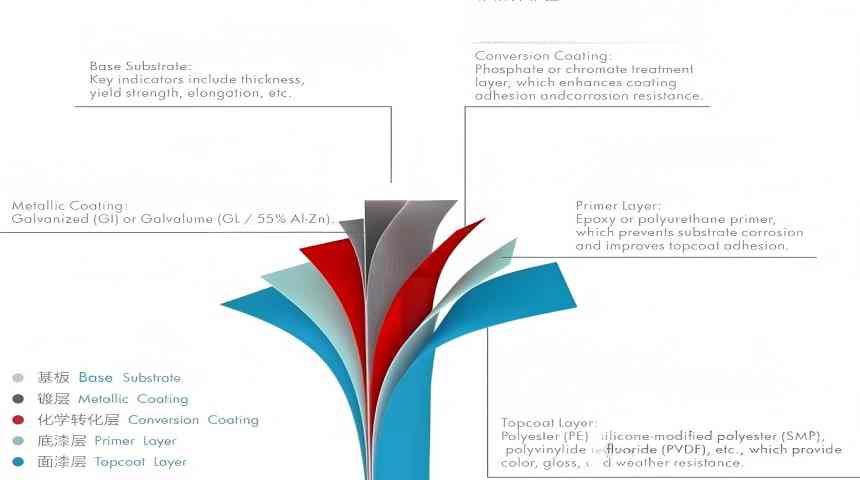

As the surface material of steel structure enclosure systems, color-coated steel sheets (also known as color-coated steel plates) are made from cold-rolled steel sheets, galvanized steel sheets, or aluminum-zinc coated steel sheets, which undergo degreasing, phosphating, and chromic acid salt treatment before being coated with organic paint (such as polyester, silicone-modified polyester, pvdf, etc.), and then baked and cured to form a composite material. This process imparts unique corrosion resistance, weather resistance, and aesthetic properties to the color-coated sheets.

Color-coated steel sheets combine the excellent corrosion resistance of coated steel sheets with a special coating system, offering superior resistance to paint film shedding, fading, and chalking. Additionally, self-cleaning coatings can be added to keep the building's appearance fresh for a long time.

In the steel structure building system, color-coated steel sheets are primarily used for walls, roofs, and special-shaped parts, forming a complete building enclosure system. They not only protect the internal structure from wind and rain but also enable architects to implement creative designs through a variety of colors and textures.

2. Core Performance

Multi-layer Protection Achieves Outstanding Performance

The reason color-coated steel sheets play such an important role in steel structure enclosure systems lies in their precisely designed multi-layer structure.

Mechanical Performance | GB/T 2518 |

Coating Performance | GB/T 13448 |

Weather Resistance | ASTM B117 |

Fire proof Performance | GB 8624 |

Environmental Performance | RoHS/REACH |

3. Application

Enclosure Scenarios for Color-Coated Steel Sheets

Color-coated steel sheets are widely applied in the construction field, primarily in two major systems: steel sheets and sandwich panels. These two systems, like "brothers," both rely on color-coated steel sheets but serve different building needs through different structural designs.

Color-coated steel sheets are applied extensively in steel structure enclosure systems, mainly covering three areas: wall systems, roof systems, and special enclosure parts.

In wall systems, color-coated steel sheets typically appear as metal sandwich panels, where insulation materials such as rock wool or polyurethane are placed between two layers of color-coated steel sheets to form a wall system with excellent thermal insulation performance. This structure not only meets building energy-saving requirements but also significantly shortens construction time.

In roof systems, the application of color-coated steel sheets focuses on waterproofing and drainage performance. Common forms include standing seam systems and overlapping systems. The standing seam system uses specialized equipment to interlock the edges of the color-coated steel sheets, forming a continuous, hole-free roof with excellent waterproofing performance, particularly suitable for large-span steel structure buildings.

Special enclosure parts include curved walls, irregular roofs, eaves, etc. These areas require higher forming requirements for color-coated steel sheets. Modern color-coating technology can now produce coating systems that can be deeply formed, allowing designers to realize their creative ideas.

4. Technical Advantages

The Value of the Color-Coated Steel Sheet Enclosure System

Lightweight and High Strength, Optimizing Overall Building Performance

The color-coated steel sheet enclosure system significantly reduces the load on the building's main structure compared to traditional enclosure materials. This characteristic not only enhances the building's economic benefits but also increases the overall stability and safety of the structure. Especially in earthquake-prone areas, it can effectively improve the building's seismic response.

Durable Weather Resistance, Facing Harsh Environmental Challenges

The system boasts excellent resistance to environmental erosion, capable of withstanding long-term exposure to harsh conditions such as coastal salt spray, industrial pollution, and ultraviolet radiation. This means the building facade can maintain its beautiful appearance for years, while its protective function remains reliable.

Efficient Construction, Significantly Shortening the Construction Period

Thanks to factory prefabrication and on-site assembly construction, the installation speed of the color-coated steel sheet enclosure system is much faster than traditional construction methods. This advantage is especially crucial in projects with tight timelines, ensuring rapid progress and early project delivery.

Green and Energy-Efficient, Aligning with Sustainable Development Concepts

The system has good thermal insulation properties and, when combined with complementary materials, can effectively improve building energy efficiency and reduce operational energy consumption. At the same time, the materials can be fully recycled, and the construction process is clean with low waste, fully embodying the principles of circular economy and environmentally-friendly construction.

These four advantages support each other and jointly constitute the comprehensive value of the color-coated steel sheet enclosure system in terms of reliability, economy, and environmental protection, providing durable and efficient cutting-edge solutions for various steel structure buildings.

5. Future Trends

Technological Innovation Driving the Upgrading of Enclosure Systems

As building technology continues to develop, the application of color-coated steel sheets in steel structure enclosure systems is also showing new trends.

Functional Integration is an Important Development Direction. Traditional color-coated steel sheets primarily serve as enclosure and decorative materials, but modern products integrate more functions. For instance, photovoltaic color-coated steel sheets combine solar cells with color-coated sheets, transforming the building enclosure system into an energy-producing system. Self-cleaning color-coated steel sheets, through special coating technology, allow surface contaminants to naturally wash away with rainwater, greatly reducing maintenance costs.

Intelligent Manufacturing is Changing the Production Method of Color-Coated Steel Sheets. Through BIM technology and production line integration, color-coated steel sheets can be personalized and precisely produced, reducing material waste and improving construction accuracy.

In industrial factory workshops, logistics warehouse, commercial buildings, and cold storage warehouse, every color-coated steel sheet quietly fulfills its mission: as a structure, it bears weight; as an enclosure, it blocks wind and rain; and as a facade, it shapes the building's image. It is the most universal and reliable "skin" and "armor" of modern architecture.

In the future, with the continuous emergence of new materials and new processes, color-coated steel sheets will continue to evolve toward higher performance, greater environmental friendliness, and smarter applications. We will continue to focus on this, with professionalism and craftsmanship, to ensure that this splash of color continues to shine with both functionality and aesthetics in the skylines and industrial spaces of more cities.