Views: 0 Author: Site Editor Publish Time: 2025-12-04 Origin: Site

Three Major Connection Methods for Portal Frame Beam-Column Joints: Flat, Vertical and Diagonal – Choose Wisely for Safety!

In the design of portal frame light steel structures, the beam-column connection detail is the core link for force transmission, directly affecting the structure's safety, cost and construction convenience.

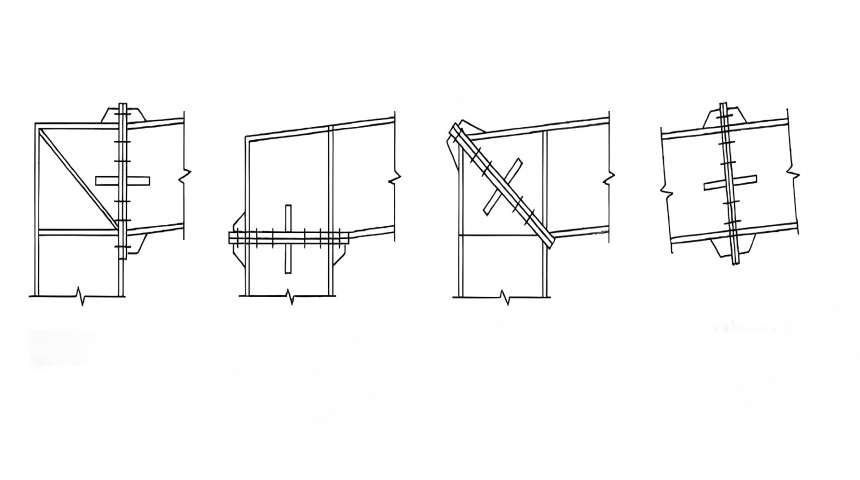

End plate connections are the most commonly used rigid connection way, which can be divided into three main types based on the placement direction of the end plate: flat, vertical, and diagonal.

What are the differences between them? Which one should be used? Today, we will explore the advantages and disadvantages of these three types of joints based on codes and engineering practices.

1. Core Differences

Let's see these three different joints.

Vertical End Plate: The end plate is perpendicular to the beam-column section, like a standing plate.

Flat End Plate: The end plate is horizontally placed, with the beam resting on top of the column.

Diagonal End Plate: The end plate is parallel to the diagonal surface of the beam, often used at the top of edge columns.

2. Advantages and Disadvantages Comparison

Each connection method has its own unique mechanical performance and applicable scenarios.

Vertical End Plate – The Most Common and Classic

| Advantages | Disadvantages |

Clear Force Transmission: Rely on the tensile resistance of high-strength bolts to resist bending moments, with shear force borne by the friction between the end plates or shear keys. The calculation model is clear, and the design is mature. | Large Bending Moments: In the case of large bending moments, multiple rows of bolts may be required, potentially causing insufficient height for the end plate. |

Strong Applicability: Suitable for beam-column connections. | High stiffness is required for the node, and reinforcing ribs are often needed. |

Large Installation Space: Provide enough space for the connection of purlins, tie rods and other secondary structure components. | If it is small steel column section, probably there is conflict between gutter and the end plate reinforcement ribs. |

The most commonly used beam-column rigid connection method in most steel structure building designs and is the first choice unless there are special requirements.

Flat End Plate – The Best Choice for Column-Top Connections

| Advantages | Disadvantages |

Favorable Force Transmission: When axial pressure from the beam end is directly applied to the column top, this pressure can effectively reduce the tensile force on the bolts, potentially reducing the number of bolts needed. | Insufficient Height: When the span is large and the beam section is much larger than the column section, the end plate section may not be high enough to arrange enough bolts. |

Easy Installation: The beam can be directly placed on the column top, making it easy to position and fix temporarily. | It is not good to connect other components at the top of the column (such as tie rods). |

Mainly used for column-top connections with steel beams. Suitable for situations where vertical loads dominate; when there is a gutter in the building, flat end plates are more advantageous than vertical ones for the layout.

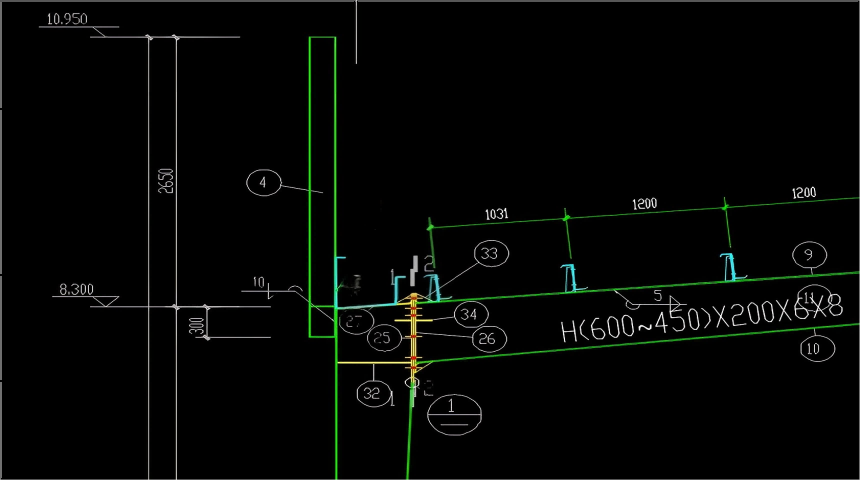

Diagonal End Plate – The "Black Technology" for Large Bending Moments

| Advantages | Disadvantages |

Longer Lever Arm: Place the end plate diagonally, the lever arm of the force transmission is effectively increased, significantly improving the bending resistance of the node. | Complex Structure: Require high processing and installation accuracy, and on-site adjustments are difficult. |

Smaller Bolt Specifications When bearing the same bending moment, the required bolt tensile force is reduced due to the longer lever arm, possibly allowing the use of fewer or smaller bolts. | Complex Force Transmission: The diagonal placement complicates the force transmission path, making the node analysis more demanding. |

Used at the top of edge columns, where the bending moment is often larger. When vertical or flat placements cannot meet large bending moment requirements, diagonal placement is an effective strengthening solution.

3. Summary and Selection Recommendations

Connection Method | Core Advantage | Typical Application | Key Considerations |

Vertical End Plate | Strong versatility, clear force transmission | Beam-column connections, beam-beam splicing (first choice) | Pay attention to shear at the node domain, and provide reinforcing ribs when necessary |

Flat End Plate | Easy installation, favorable force transmission | Column-top connections, vertical loads dominate | Ensure matching beam-column section height, avoid insufficient end plate height |

Diagonal End Plate | Long lever arm, strong bending resistance | Edge column top, large bending moment conditions | Design as semi-rigid connection, requires high processing and installation precision |

Core Principles:

Safety First: No matter which method is chosen, the node's bearing capacity must exceed that of the component, adhering to the principle of "strong node, weak component."

Consistency with Model: The chosen node stiffness (rigid, hinged, semi-rigid) must match the assumptions in the calculation model.

Considering Cost and Construction: Choose solutions that facilitate factory production, transportation and installation while ensuring safety, which can save significant costs and construction time.

Qingdao Xinguangzheng Steel Structure possessed large precise and advanced equipments and production lines such as Assembly Machine, Single-armed Type SAW Machine, Shot Blasting Machine, Flaming Cutting Machine, CNC Intersecting line Cutting Machine, Purlin Machine, Corrugated Steel Sheet Production Line, Sandwich Panel Production Line, etc.

Built on over 28 years of steel structure experience, our products had been exported to more than 110 countries & regions around the world, both of our company and products are well received and got high reputation at home and abroad.